Can you explain to me why we have to use filters that are HEPA when we are trying to remove stuff from the air that is larger than 0.3 microns? In other words can we use a filter that is rated for one micron and be just as effective?

Rather than answer the question directly, I'd like to explain why we use high efficiency particulate air (HEPA) filters in general.

HEPA filters are made with randomly arranged fibers that may range in size from one to 50 microns in diameter. Fibrous filters are designed for various applications using a variety of fiber materials. It is not uncommon that the space between these fibers is larger than 0.3 microns. The idea that the pores in a HEPA filter are smaller than the smallest particulates that they collect is incorrect.

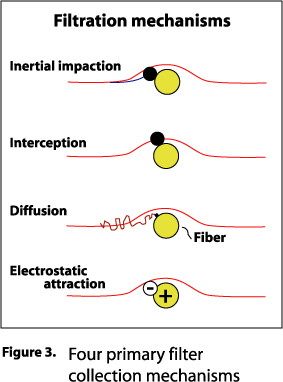

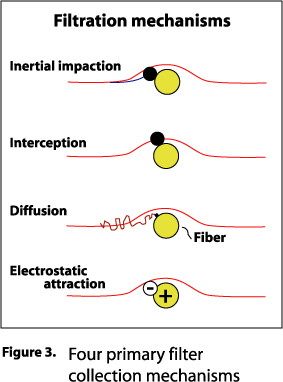

There are several filtration mechanisms interacting simultaneously that govern filter performance and efficiency. These mechanisms include:

- Impaction — Impaction occurs when a particle traveling in the air stream and passing around a fiber, deviates from the air stream (due to particle inertia) and collides with a fiber.

- Interception — Interception occurs when a large particle, because of its size, collides with a fiber in the filter that the air stream is passing through.

- Diffusion — Diffusion occurs when the random (Brownian) motion of a particle causes that particle to contact a fiber.

- Electrostatic attraction — Electrostatic attraction plays a very minor role in mechanical filtration. After fiber contact is made, smaller particles are retained on the fibers by a weak electrostatic force.

[Figure 1 – Filter mechanisms] adapted from NIOSH

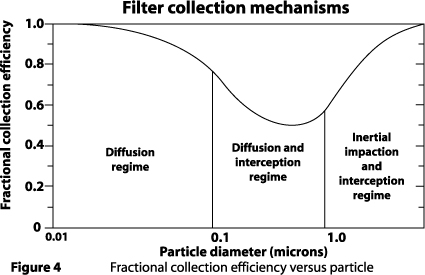

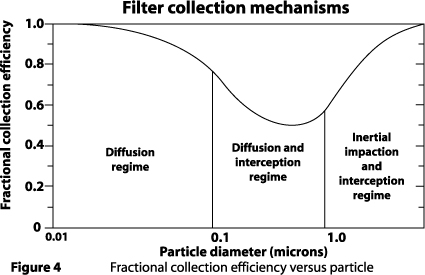

According to the National Institute for Occupational Safety and Health (NIOSH) impaction and interception are the dominant collection mechanisms for particles greater than 0.2 micron, and diffusion is dominant for particles less than 0.2 micron. Filters use an efficiency rating system based upon the most penetrable particle size (MPPS). MPPS is the particle size that at which the filter efficiency is at its minimum. For various reasons, it is generally accepted that the MPPS for HEPA filters is 0.3 microns. Depending upon a number of factors, the MPPS has been stated as being between 0.12 and 0.3 microns.

Aerosolized particles larger than the MPPS will tend to flow within an air stream. They possess a certain mass and velocity which allow them to stay in the air stream. As air flows around a filter fiber, some larger particles, especially those that are larger than one micron, will collide (inertial impact) with or be intercepted by the fiber. Below the MPPS, Brownian motion of the particles aids the filter in removing these smaller particles. Brownian motion occurs when these particles collide with air molecules and are bounced around. This causes them to deviate from the flow of the air stream and therefore take an erratic path that increases their likelihood of impaction on the filter media. Additionally, the MPPS is dependent upon a number of operating conditions including filter surface area, air flow rate, and differential pressure across the filter. Therefore, HEPA filters are more efficient above and below the MPPS and are least efficient at the MPPS.

[Figure 2- Filter collection mechanisms] adapted from NIOSH and Lee et al. 1980

There are various rating systems for filters. They are commonly rated based upon their collection efficiency, pressure drop and particulate-hold capacity. In the United States, there are two test methods used; American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Standard 52.1-1992 and 52.2-1999

HEPA is a term that has been used to describe a filter that is efficient at removing 99.97% of particles at 0.3 microns. There are classes of HEPA filters that are more efficient than 99.97%. A class "C" HEPA filter is efficient at removing 99.99% of particles at 0.3 microns. There are also filters that are referred to as Ultra Low Particulate Air (ULPA) filters and have a minimum filtering efficiency of 99.999% at 0.12 microns. ASHRAE Standard 52.2 has established the minimum efficiency reporting value (MERV) which quantifies the filters efficiency in different particle size ranges for a clean and incrementally loaded filter to provide a composite value. The MERV rating system grades filters on a scale from one to 20. A filter that can remove 99.97% of particles from 0.3 to one micron in size is rated as a MERV 17. The best one micron filter is a MERV 16 rated at 95% efficiency.

As an example, I used a particle counter and determined the following indoor/outdoor particle concentrations per cubic foot of air.

Particles per cubic foot

| |

Outside air |

Inside air |

| 0.3 micron |

~2,000,000 |

~1,000,000 |

| 1.0 micron |

~30,000 |

~8,000 |

If a 2,000 cfm air filtration device with a properly installed HEPA filter was set up in a room, it would process ~2,000,000,000 particles at 0.3 microns and 16,000,000 one micron particles per minute. Based upon the inside air concentrations, the table below shows the number of particles for each particle size that could pass through the filter and be exhausted from the air filtration device.

Number of particles that pass through the filter per minute

| |

0.3 micron |

1 micron |

MERV 16

(1 micron filter) |

~100,000,000 |

~800,000 |

| MERV 17 (HEPA) |

~600,000 |

~4,800 |

The HEPA filtered air would be 167 times cleaner than the air exhausted from the one micron filter. Keep in mind that these numbers are based upon ambient uncontaminated air. Studies have shown that during remediation that there can be several orders of magnitude difference between the ambient uncontaminated air and the remediation workplace.

It is true that most mold spores of concern to remediators are larger than 1 micron. However, when performing activities that require the use of air filtration devices, there are particles that are smaller than one micron. You also need to be concerned about mold fragments and some bacteria. Bacteria can approach the 0.3 micron size. One source stated that ~90% of all particles in the air are around the 0.3 micron size. The decision to use HEPA filters is also based upon its economics. While the use of ULPA may provide a higher level of filtration, it adds unnecessary cost. The use of a one micron filter would be less expensive but would not provide the level of filtration that would best protect workers and the indoor environment. Finally, the manufacturers of air filtration devices were already producing equipment for the asbestos abatement and other industries that used HEPA filtration. These units had already stood the test of time by demonstrating their effectiveness.

— Jim Holland

I have recently noticed that when I first turn on my refrigerant dehumidifiers they emit an unpleasant odor. Can bacteria be growing in the dehumidifier? Can this cause any other problems? How do I prevent this from happening?

Most people believe that the water, in the drain tank of their refrigerant dehumidifiers, is clean. The liquid water that is collected, as a result of condensation, is expected it to be similar in purity to distilled water.

Unfortunately, there is also the potential that airborne particles and bioaerosols may become mixed with the water. As the fan moves air across the AC coils of a refrigerant dehumidifier, aerosolized particulates travel with it. Some of these particles impact onto the wet surfaces of the coils and become trapped in the water film which then drains into the holding tank. Over time, particles can accumulate in the tank. A residue may adhere to the wall of the tank and not be pumped out. Other particles can accumulate on the coils, reducing their ability to remove moisture efficiently.

Airborne particles may include bacteria, mold spores and other organic material that may be a food source for the bacteria and molds to grow. On a sewage loss it is possible that some of these bioaerosols can be toxigenic, pathogenic or allergenic. Left unattended, there is also the remote possibility of creating a potential health risk. As these organisms grow, they may produce odors in the form of microbial volatile organic compounds (mVOCs). These mVOCs are byproducts of digestion, in the form of gases, which can accumulate and be dispersed in high concentration when the unit starts up, creating that burst of odor you mentioned.

Growth on AC coils is slowed by the cold temperature, but when the unit is turned off the coils can warm up. As long as moisture and a food source are present, microbial growth can occur.

Water pumped from the drain pan may have some potential contamination, from exposure to the air that may be contaminated or from a poorly maintained drain pan. Realistically this situation is unlike to result in a major exposure risk, especially if the water was continuously being pumped out of the tank and back into the sanitary sewer system. In addition, if the air is contaminated sufficiently to create a problem in the dehumidifier drain water, the air itself would normally be considered a much greater hazard.

Many refrigerant dehumidifiers today have filters that trap some of these aerosolized particles before they get into the unit. The more efficient the filter, the fewer and smaller the particles that will make their way into the machine. This should result in fewer problems with microbial growth and resultant odors and potential health effects; however, few if any commercially available refrigerant dehumidifiers have HEPA or other high-level filtration systems, which would be necessary to prevent this problem completely.

To keep these potential problems from getting out of hand, you need to implement two common-sense rules for the prevention of microbial growth:

- Keep it dry, and nothing will grow.

- If you cannot keep it dry, and the surface is non-nutritive, then keep the surface clean to prevent or at least minimize microbial amplification.

While refrigerant dehumidifiers are operating, you cannot keep the exposed surfaces dry, as condensation is necessary for the machine to perform as they are designed. However, since the exposed surfaces are non-nutritive, all you need to do is keep them clean to minimize microbial amplification.

I recommend you clean dehumidifiers thoroughly after each job and before they go out to the next job. Exact procedures vary by model, but a thorough cleaning/decontamination process would generally involve disassembly; thorough cleaning of the coils; drain pan and exposed surfaces; cleaning or replacement of the filter; and reassembly. Consult the manufacturer instruction for cleaning/decontamination procedures suitable for that particular model. Inappropriate cleaning procedures may damage the unit.

When the dehumidifier has been used on a bacterially contaminated project, you might want to consider using, as part of the cleaning process, a biocidal product registered with the EPA for use on equipment. Follow the label instructions and wear appropriate personal protection equipment if required.

Refrigerant dehumidifiers vary significantly in how difficult they are to disassemble, clean and reassemble. You might want to take this into account when purchasing equipment. In a severely contaminated environment, you might also want to preferentially use equipment that is easier to decontaminate.

— Jim Holland

What is the difference between a “high-efficiency” vacuum cleaner and a “HEPA” vacuum?

There are two reasons why "high efficiency" vacuum cleaners are not considered "HEPA" vacuums.

- Not all vacuums marketed as "high-efficiency" contain a true HEPA filter.

- Not all vacuums that incorporate a true HEPA filter actually filter at true HEPA levels.

Not all vacuums marketed as "high-efficiency" contain a true HEPA filter.

A HEPA (High Efficiency Particulate Air) vacuum contains a filter that consistently filters out at least 99.97% of the airborne particles that are 0.3 microns in size or larger. These filters were originally developed during WWII to protect atomic industry workers from radioactivity carried on extremely fine dust particles. HEPA vacuum cleaners have become very popular in recent years, due to increasing (and justified) public concern about whether vacuum cleaners adequately filter out allergens and other particles.

One consequence of this popularity is that some manufacturers now market vacuum cleaners using such terms as HEPA-like, HEPA-type, high-efficiency or with other wording to indicate that their filters are more efficient than older-style vacuums. Some consumers jump to the conclusion that all "high efficiency" filters or vacuums operate at true HEPA filtration levels. This is not true.

Some filters marketed this way provide significantly higher level of filtration than standard filters, especially for larger particles. Depending on the intended use of the vacuum cleaner, this level of filtration may be entirely adequate. However, for situations where a true HEPA vacuum is needed (e.g. performing lead, asbestos or mold remediation) only a vacuum cleaner certified by the manufacturer as providing HEPA filtration should be used.

Not all vacuums that incorporate a HEPA filter actually filter at true HEPA levels.

A lot of confusion with regards to filtration efficiency is a result of not understanding the difference between the efficiency of a filter and the efficiency of a machine that incorporates the filter.

For purposes of illustration, let's assume a vacuum system has a filter that is 100% efficient at removing particles .3 microns and larger from the airstream. A logical assumption would be that the vacuum cleaner as a whole is 100% efficient at .3 microns. However, what happens if only 50% of the air going through the machine actually passes through the filter? This can happen due to internal design, leakage around seams, seals and gaskets, etc. In this case, the machine is removing only 50% of the particles of this size (50% efficiency), despite the fact that it contains a 100% efficient filter.

Assume the following (all numbers are theoretical):

- A vacuum system with airflow of 100 cfm contains a true HEPA filter which removes 99.97% of the particles 0.3 micrometers and larger that pass through it.

- Air being pulled through this system averages 100,000 particles in this size range per cubic foot. (This is unusually clean air.)

- Therefore 10,000,000 particles pass through the machine each minute.

| Percentage of air passing through filter |

Percent filtration efficiency of vacuum system |

Particles per minute in exhaust air |

| 100.0 |

99.97 |

3,000 |

| 99.9 |

99.87 |

13,000 |

| 99.5 |

99.47 |

53,000 |

| 99.0 |

98.97 |

103,000 |

| 95.0 |

94.97 |

503,000 |

| 90.0 |

89.97 |

1,003,000 |

As the table illustrates, unless the vacuum cleaner is designed and built so that it is fully sealed (100% of the air pulled in through the nozzle actually passes through all filters, especially the HEPA filter), theoretical efficiency of its filters is somewhat irrelevant. Unfortunately, building a fully sealed machine is both difficult and expensive. It requires precision in manufacturing, and expensive attention to details of seals and gaskets.

Additional thoughts about HEPA vacuums

HEPA vacuums (as defined above) tend to be significantly more expensive than non-HEPA units, even those that are "high-efficiency." The HEPA filters themselves are also quite expensive. The cost for some HEPA filters can exceed several hundred dollars. For this reason, most HEPA vacuums contain a number of prefilters to catch the larger particles that can help to extend the life of the HEPA filter. All of these filters must be regularly maintained in order to function properly. You should expect maintenance of a HEPA vac to require more time and attention than a more "standard" vacuum.

A laser particle counter can be used to measure the size and number of particles in the exhaust of a HEPA vacuum. This allows the user to monitor whether the machine and its filters are functioning properly.

The HEPA filter may be located either in front of or behind the vacuum motor. Either system works, when properly engineered. One advantage of locating the filter behind the motor is that the HEPA filter will catch the small carbon and other particles given off by the motor. This can make the use a laser particle counter more efficient when attempting to determine whether the unit is filtering properly.

Any vacuum that is not initially designed to provide HEPA filtration is unlikely to achieve true HEPA performance. Some manufacturers produce vacuums that they claim filter at HEPA levels, but without using an actual HEPA filter. Instead, they use a series of bags and filters in a fully-sealed system, designed so that the system as a whole performs at HEPA filtration levels.

Wet-dry HEPA vacuums are also available. They are usually more expensive than HEPA dry-vacuums, and care must be taken to ensure that the HEPA filter remains thoroughly dry while not in use. Many HEPA filters are manufactured from materials that are excellent food sources for mold when there is enough moisture present.

Most HEPA vacuums are a tank or canister type. They are extremely versatile, and are probably the type most common used by cleaners. Some may have a motorized brush attachment that allows them to be used for vacuuming carpet. Upright vacuum cleaners that filter at HEPA levels are also available.

European vacuums may list an S-class filter, which is equivalent to a HEPA filter.

ULPA filters and vacuums

There is an even higher level of filtration available, ULPA (99.999% efficient at .12 micrometers). This level of filtration is widely used in pharmaceutical labs, electronics cleanrooms, and in other situations where the highest possible level of air cleanliness must be maintained. ULPA filters and vacuums are considerably more expensive, clog faster and are seldom necessary for abatement or remediation projects. A few HEPA vacuums can be converted to an ULPA vacuum simply by replacing the HEPA filter with an ULPA filter.

— Jim Holland

An Environmental Consultant has recommended blasting with soda or some other media for mold remediation. I’ve never used this type of process. How does it work and are there any problems I should be aware of?

Blast cleaning is a group of cleaning methods in which abrasive media particles are introduced into an air (or sometimes water) stream, which is then directed at a surface to clean it. There are many media types in use, including soda (sodium bicarbonate), as you mentioned. Media types include steel grit, water ice chips or flakes, plastic chips, walnut shells, dry ice, sponges embedded with a variety of media, and others.

In this article, we will first discuss the characteristics of blast cleaning in general, and then those of two specific media.

Air pressure, volume, and the distance the media has to travel to the surface after injection all significantly affect the aggressiveness of blast cleaning methods, as do the density, hardness, weight, size and other characteristics of the media used. The ability to adjust these many variables individually makes blasting an extremely versatile system of cleaning. Some blast methods are so gentle they can remove graffiti from painted surfaces without damaging the paint beneath. Others are so aggressive that they can deeply "profile" a steel plate surface for better paint adhesion.

Two main uses for blasting have gotten a lot of attention recently in the cleaning/restoration industry. These are: removing charred wood and smoke residue from framing after a fire, and removing mold growth from wood framing (and sometimes other surfaces) during mold remediation. In both applications, blasting is very effective at thoroughly cleaning the intricate surfaces which are so labor-intensive to sand, scrape or wire brush manually.

When media blasting is used for these purposes, we should keep in mind what blasting actually does. Most blast media will do a great job of removing char, smoke or mold growth from wood framing. However, when the contaminant comes off the surface, it does not disappear. Instead, it aerosolizes and creates worker exposure levels that probably exceed those created by any other method of cleaning.

High-pressure water washing is similar in many ways to blast cleaning methods, using the water stream itself as a "blast" media. Air washing is a method of cleaning that is essentially blast cleaning without any media. Both, like blasting, do an excellent job of aerosolizing particles from a surface, although air washing is often ineffective if the particles are adhered to the surface. Air washing, using a variety of delivery mechanisms, is often used as a component of air duct cleaning.

The aerosolization caused by blasting is not always a problem. For instance, if mold remediation is done outdoors or in an unenclosed space such as a structure that has not yet been closed in, the mold spores are able to just disperse. This assumes unprotected people are far enough away as to not be endangered and that contaminants are not being drawn into a building. Contents can be effectively and safely cleaned using blast methods either outside or in a true laminar airflow cleaning chamber.

There is another possible problem when blasting is used for mold remediation or for cleanup of other types of potentially hazardous particles. Most mold spores are 1–2 micrometers and larger. Thus they can be effectively removed from the air by HEPA filters (99.97% efficient at 0.3 micrometers) in respirators, vacuums and air filtration devices. It has been speculated that the harsh mechanical action of blasting may break apart mold spores into smaller particles, some of which are likely to be smaller than 0.3 micrometers. Since this kills the spore, there is no chance that it could cause an infection. However, the primary health effects of mold are allergic and perhaps toxic, not infectious. These effects are not reduced by being broken into very small particles. If this speculation is correct, these particles could pass right through HEPA filtration, potentially creating exposure and cross-contamination issues. Similar problems could perhaps arise when blasting is used to remove lead paint or other hazardous contaminants.

Most common media types, such as sand, are overly aggressive for the purposes mentioned above and cause unacceptable appearance or even structural damage to wood surfaces. Almost all media types, such as sodium bicarbonate ("soda"), leave a large amount of used media that must be cleaned up, in addition to the removed contaminants.

Some media, such as plastic chips and sponges with embedded abrasives, are designed to be recycled to make their use cost-effective. Recycling may be feasible for fire restoration uses, but according to IICRC S520 recycling of media used for mold remediation is not advisable, as it is not known whether present methods of recycling are adequate to remove mold contaminants effectively. So for mold remediation, these "recyclable" types of media should only be used once, which usually makes them prohibitively expensive.

Yet another potential disadvantage of blasting is that concentrated air pressure at the point of contact with the surface being cleaned has significant potential to force air, media and entrained contaminants through building penetrations into uncontaminated areas, even if the work area is kept under negative pressure.

Most blasting methods require a considerable investment in equipment and a significant amount of time to set up, which means that their use is a lot less efficient on smaller jobs.

Safety precautions necessary with any blast method may include eye, face, and respiratory protection. Most blast methods are very noisy, so hearing protection must be used.

The two most widely used media for restoration and mold remediation are soda and dry ice. We'll discuss these two individually.

Soda blasting is very effective at removing char, smoke residue and mold growth from framing without causing excessive damage to the wood. This is because the soda media is very soft.

Unfortunately, soda blasting produces a tremendous amount of very fine dust and leaves a lot of debris from the expended media that can be difficult and time-consuming to clean up. It has a fairly high production rate.

Dry ice blasting is certainly the most unusual of the blast media. It uses pellets or shavings of dry ice (solid CO2) as a blast media, which eliminates some of the disadvantages of other media.

Unlike other media, dry ice sublimates (goes from a solid to a gas without passing through a liquid phase) on impacting the surface being cleaned. When it goes from a solid to a gas, it tends to spread out across the surface of the material which causes a "shearing" effect that efficiently removes contaminants from the surface while causing little if any surface damage. For certain types of contaminants, such as oils and waxes, thermal shock also contributes to the cleaning effect. As the blast media becomes a gas and dissipates, only the contaminants removed from the surface are left to be cleaned up. Highly efficient removal of contaminants, minimal surface damage and no media residue to clean up seem to make dry ice blasting the ideal mold remediation method.

However, dry ice blasting has all the disadvantages of blasting in general, with the exception of a media waste stream, and it has some very serious and specific safety concerns. These can all be overcome, but you should plan before using this cleaning method.

Dry ice blasting methods vary considerably. Some use prepared pellets, while with others the machine generates its own pellets or flakes from blocks of dry ice. Dry ice media is significantly more expensive than most others, inherently inconvenient and potentially hazardous to handle. Some methods have a much higher production rate than others. The amount of dry ice used varies from as little as ¼ pound per minute to more than 10 pounds per minute.

The surface temperature of dry ice is -110°F, more than adequate to cause serious damage to human skin. Heavy gloves should always be worn when handling dry ice or its containers. Use tongs when handling dry ice blocks.

CO2 gas is 1.56 times as heavy as air. Since it fills up a space from below, it displaces oxygen and can potentially create a highly hazardous reduced-oxygen atmosphere. High concentrations of CO2 gas also have direct health effects, even if the oxygen level remains adequate. Containment may limit ventilation enough that excessive levels of CO2 may build up. Keep in mind that such a high-volume blast system adds a tremendous amount of air to the space (as propellant), in addition to the CO2. To maintain appropriate negative pressure differentials, you may have to significantly increase your volume of exhaust air.

We attempted to find some information on CO2 levels that are typically generated during dry ice blasting. We were unable to find any information that would allow us to report exposure levels. However, in small areas or confined spaces, especially one that is below grade, such as a crawlspace, these issues could become critical.

The OSHA Permissible Exposure Limit (PEL) for CO2 gas is 5000 ppm (0.5%) for an eight-hour time-weighted average; 40,000 ppm (4%) is the Immediately Dangerous to Life and Health (IDLH) concentration. Engineering controls, such as exhaust fans (HEPA filtered if the air being exhausted is or may be contaminated) at ground level may be able to keep it below these levels, if properly used.

Supplied-air or self-contained (SCBA) respirators must be used if engineering controls do not keep levels below the PEL. Continuous monitoring of CO2 levels, at least in confined spaces, is required to ensure worker safety.

According to the Canadian Centre for Occupational Health and Safety, "Exposure to 10% for 1.5 minutes has caused eye flickering, excitation and increased muscle activity and twitching. Concentrations greater than 10% have caused difficulty in breathing, impaired hearing, nausea, vomiting, a strangling sensation, sweating, stupor within several minutes and loss of consciousness within 15 minutes. Exposure to 30% has quickly resulted in unconsciousness and convulsions. Several deaths have been attributed to exposure to concentrations greater than 20%. Effects of CO2 can become more pronounced upon physical exertion, such as heavy work."

Blast methods of cleaning are extremely versatile and potentially have many uses in the restoration and remediation industries. However, inherent characteristics can cause undesired side effects if not adequately addressed.

— Jim Holland

Is there any value in setting up an air scrubber in a Category 1 (clean source) water loss?

I am in favor of using Air Filtration Devices (AFDs) on water losses. But, let me begin by making sure we are using the same terminology. The following is a general discussion of how the industry has been using several terms.

Air filtration devices are machines that are used to filter the air. An air scrubber is an AFD that is being used to filter recirculated air within a work space. A negative air machine is an AFD that is being used to filter air and create negative air pressures within a work space. In many cases the AFD can be used interchangeably to "scrub" the air, create "negative air" or create a "positive air" pressure. Therefore, an AFD can be a versatile piece of equipment that is easily adapted to perform some or all of these functions.

Some restorers are setting up AFDs as a negative air machine on any category of water loss as a precaution. This practice is beneficial for several reasons including minimizing contractor’s liability.

Others are setting up AFDs as air scrubbers. This practice may provide some benefit, but the end result may not be a clean indoor environment for several reasons. There is an area around the intake of an AFD that is called the “capture zone”. Within this area, the AFD can capture 100% of any particulates or bioaerosols that enter into it. Typically the capture zone of a large HEPA filtered AFD does not extend much more than 3 feet out from the intake. Because the capture zone is so small relative to the room, it may not capture as much of the contaminants as you might think. Keeping in mind, that an "air scrubber" recirculates the filtered air within the room, the exhaust side of the AFD may do more harm than good by blowing contaminants, if present, to other parts of the building. This problem could be minimized by the use of a diffuser on the exhaust side of the AFD. On the other hand, an AFD used as negative air machines can help control an environment by keeping the moisture and potential contaminants from going elsewhere.

The US Environmental Protection Agency has published a document called Residential Air Cleaning Devices: A Summary of Available Information. This document was prepared for residential air purifiers, but many of the same comments apply regarding commercial AFDs being used as scrubbers. This document states:

"The three strategies (in order of effectiveness) for reducing pollutants in indoor air are source control, ventilation, and air cleaning. Source control eliminates individual sources of pollutants or reduces their emissions, and is generally the most effective strategy. Some sources, like those that contain asbestos, can be sealed or enclosed; others, like combustion appliances, can be adjusted to decrease the amount of emissions. Unfortunately, not all pollutant sources can be identified and practically eliminated or reduced. Ventilation brings outside air indoors. It can be achieved by opening windows and doors, by turning on local bathroom or kitchen exhaust fans, or, in some situations, by the use of mechanical ventilation systems, with or without heat recovery ventilators (air-to-air heat exchangers). However, there are practical limits to the extent ventilation can be used to reduce airborne pollutants. Costs for heating or cooling incoming air can be significant, and outdoor air itself may contain undesirable levels of contaminants. Air cleaning may serve as an adjunct to source control and ventilation. However, the use of air cleaning devices alone cannot assure adequate air quality, particularly where significant sources are present and ventilation is inadequate."

As you can see, air cleaning is considered to be the least effective method for reducing pollutants in indoor air. In a situation where a Category 1 water loss has occurred, your goal is to dry the wet areas, prevent secondary damage from moisture, and control pre-existing contaminants. Most buildings have substantial dust and debris accumulated in and under carpeting. It is also possible to have concealed mold growth that is not part of the water loss. If you don't know the source, then “source control” is impossible; therefore, the use of an AFD is a precaution.

Ventilation, on the other hand, may be possible by using the AFD as a negative air machine and allowing filtered outdoor air to enter into the work space. Of course this can only be achievable in an open drying system.

There are several advantages to drying a building under negative pressure. First, it will prevent dust and debris from being forced, by air pressure, into other parts of the building. Also, moisture flows from areas of higher air pressure to areas of lower air pressure. By creating a negative air pressure, the moisture in wall cavities or other spaces will be more likely to be drawn into the negatively pressurized room where dehumidification can remove it. A final advantage is that negative air pressure is less likely to cause particulates and biocontaminates to become aerosolized.

In order for an AFD to be effective in removing particulates from the air, it must be adequately sized and the filters must be able to remove a sufficient amount of the particulates that pass into the unit. An efficient filter that removes 100 percent of particles is not helpful if it is only able to move a low amount of air. Some of the factors that influence the ability of an AFD to remove particles from the air include the size and mass of the particle, filter loading, air that bypasses the filter and is drawn around it, and how well the air mixes in the room.

There are several methods that have been adopted for measuring the effectiveness of filters. The weight arrestance test is generally used to evaluate filters that have low efficiencies. These typically are the common mechanical filters used in HVAC systems and do not provide an adequate evaluation of smaller respirable-sized particles such as molds or bacteria. The atmospheric dust spot test is generally used to evaluate medium efficiency filters. This also does not provide an adequate evaluation of smaller respirable-sized particles such as molds or bacteria. Dioctylphthalate testing (DOP testing) has been used to rate high efficiency air filters. This uses a particle of a known size that is released into one side of a filter and then measured on the clean side of the filter. By measuring the amount of particle that penetrates the filter you can determine the filters efficiency. Typically a HEPA filter is 99.97% efficient at .3 microns. DOP testing provides a better assessment of the ability to capture the smaller respirable-size particles. It is important to understand whether the test was performed on the filter alone or the AFD with the filter installed. There is currently a movement away from DOP testing to other methods. Since AFDs can have bypass, merely testing the filter outside of the machine isn’t a sufficient indication of how well the total system works. There are other factors that impact the filters efficiency including particle shape and flow rate.

Another filter rating system that is beginning to gain some popularity is the MERV system established by the American Society of Heating Refrigeration and Air Conditioning Engineers (ASHRAE). This rating system has achieved some level of acceptance since the EPA in their document Mold Remediation in Schools and Commercial Buildings recommends using a MERV 8 or higher. However, very few manufacturers are offering MERV ratings for their equipment at this time. Until a standardized system of rating air cleaners is utilized, it is frequently up to the buyer to decide what their evaluation criterion should be.

Most of you are familiar with the Association of Home Appliance Manufacturers (AHAM) rating system for dehumidifiers. AHAM has also developed an American National Standards Institute approved (ANSI) standard for portable air cleaners. This rating system is referred to as the "clean air delivery rate" or CADR. It is used to rate the effectiveness of room air cleaners for tobacco smoke, dust and pollen. Unfortunately at this time, they do not rate systems for other small particles such as mold or bacteria, which are one reason why an air cleaner might be used. The CADR takes into consideration the filter efficiency, air flow and pressure drop.Currently, the CADR is not commonly being used to rate AFDs for biological contaminants.

Under the right conditions, some air-cleaning systems can effectively remove certain particles, although the particles must be suspended in the air. The suspended particles must then be able to move to or be drawn to the capture zone of the AFD in order to be removed.

At this time there is controversy about how effective AFDs are, when used as scrubbers. An ad hoc committee convened by the FDA in 1987 concluded: "The data presently available are inadequate to establish the utility of these devices in the prevention and treatment of allergic respiratory disease."1

It is also recognized that not all air filtration systems work equally well. Unfortunately, there is no one single method for evaluating these systems so they can be compared. At this time, no government standards exist for rating air cleaners or scrubbers — although private standards have been established. Furthermore, only particle removal is evaluated with no guidelines for the comparative ability of air cleaners to remove gases.

Air cleaning may achieve an additional reduction in the levels of certain pollutants when source control and ventilation do not result in acceptable pollutant concentrations. However, air cleaning alone cannot be expected to adequately remove all of the pollutants present in the typical indoor air environment. Consider these factors:

- The potential effectiveness of the device under the conditions it will be used;

- The need for routine maintenance, including cleaning and replacement of filters;

- The estimated capital and maintenance cost;

- The installation requirements (e.g., power, access);

- The manufacturer's recommended operating procedures;

- The possible production or redispersal of pollutants;

- The inability of air cleaners designed for particle removal to control gases and some odors, such as those from tobacco smoke;

- The noise level at the air flow rates that will be used.

If you are going to use an AFD as an air scrubber or as a negative air machine, consider using a particle counter prior to, during and after turning off the AFD to measure the efficiency of the system that you have set up. By measuring the particle levels, you can determine whether or not and to what extent the system is beneficial.

1Nelson HS, Hirsch SR, Ohman JL, PlattsMills TAE, Reed CE, Solomon WR. 1988. Recommendations for the use of residential air-cleaning devices in the treatment of allergic respiratory diseases. Journal of Allergy and Clinical Immunology 82(4): 661-669.

— Jim Holland